Programs can be prepared in advance without tying up the press brake, reducing machine idle time.

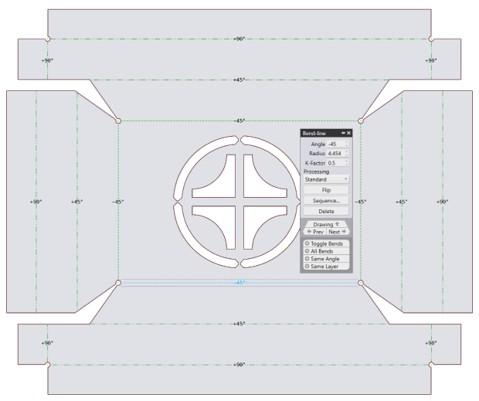

Full simulation of bend sequences, collision detection and design alerts help low possible mistakes.

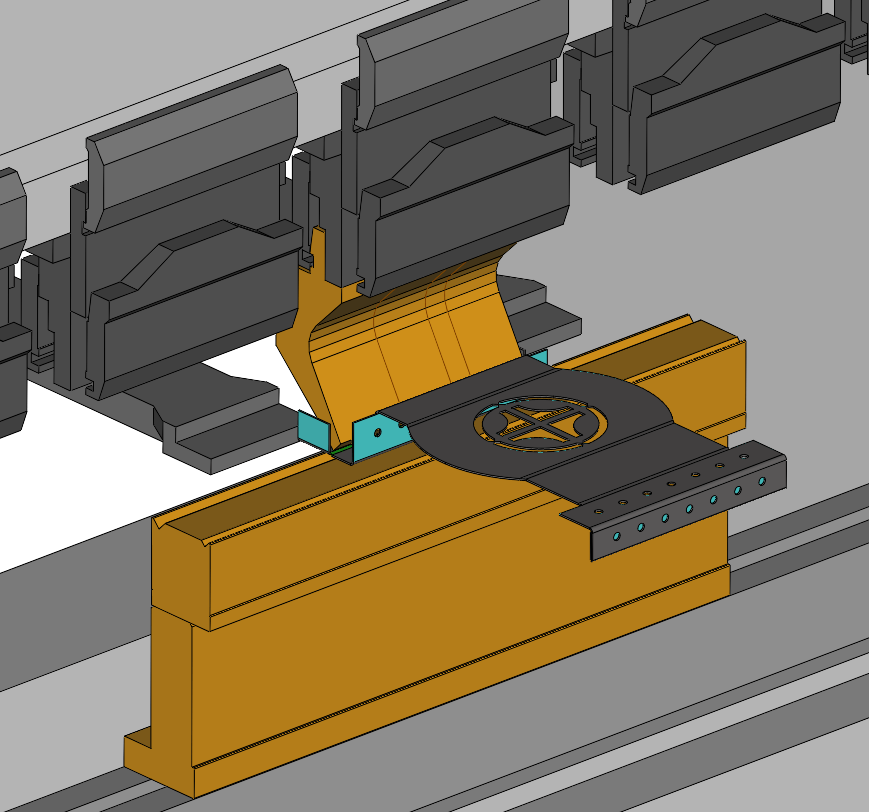

Multi-bend or multi-setup solutions calculated effortlessly based on the availble tools and machine parameters.

Reduce trial-and-error on your machine, tooling and sequences can be optimised offline.

更少的废料、更短的机器停机时间和更快的吞吐量可降低总体生产成本。.

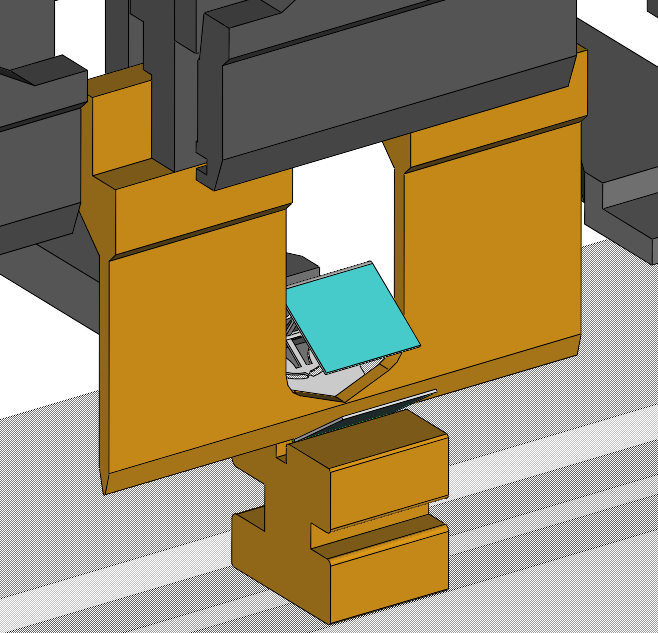

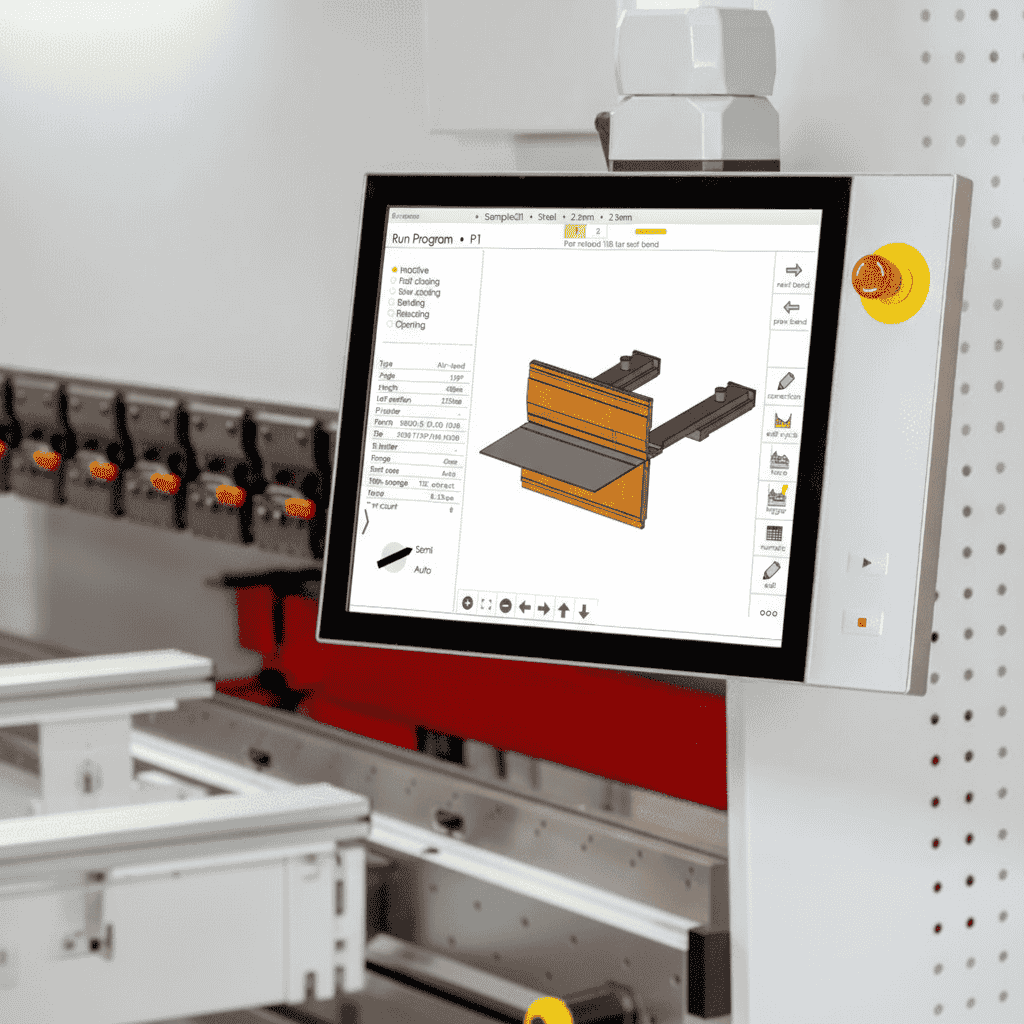

Fully integrated with the JFY TJS-90 HMI controller.

JFY CUT supports a wide range of import formats, including DXF, DWG, ACIS, Inventor, CATIA, I-Deas, IGES, MetaCAM, SolidEdge, Pro-E, and SolidWorks, making it highly compatible with many CAD formats without the need for time-consuming file conversions, maintaining the integrity and accuracy of the original part geometry.

In addition, JFY CUT features a powerful and user-friendly editor that allows you to convert 2D designs into fully realized 3D models. This capability enables quick validation, modification, and preparation of parts for bending processes, reducing design errors and streamlining production.

JFY BEND 具有智能折弯解决方案,旨在优化工具选择、零件放置和多级设置,帮助制造商实现更快、更精确和更高效的生产。通过分析折弯过程,该软件可以推荐最佳工具和顺序,减少不必要的工具更换,并确保以最有效的顺序加工零件,从而节省时间并最大限度地减少错误。

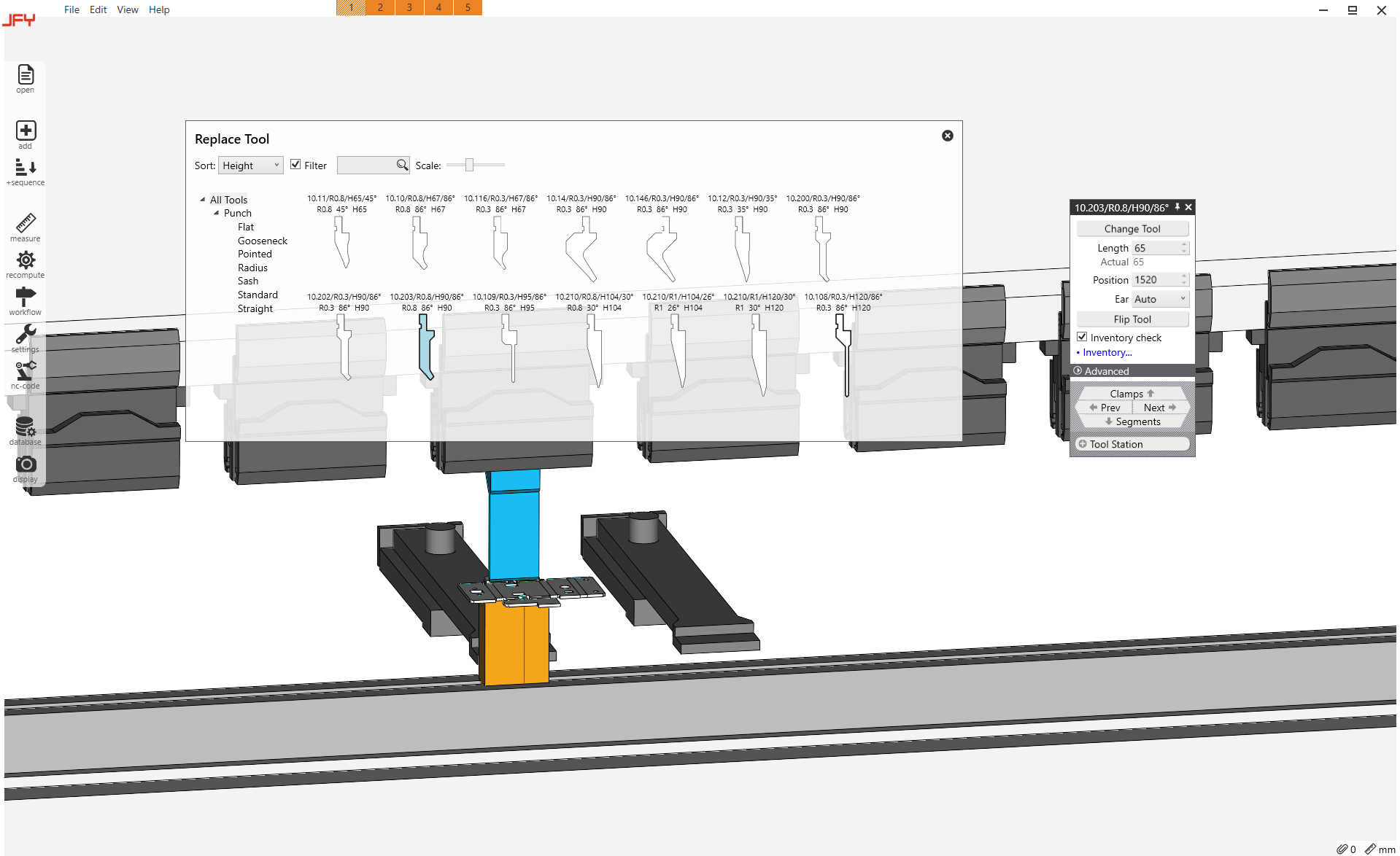

JFY BEND 还拥有一个完全沉浸式的编辑器,您可以与屏幕上的项目(如量具、工具、零件和工具架)进行完全交互。

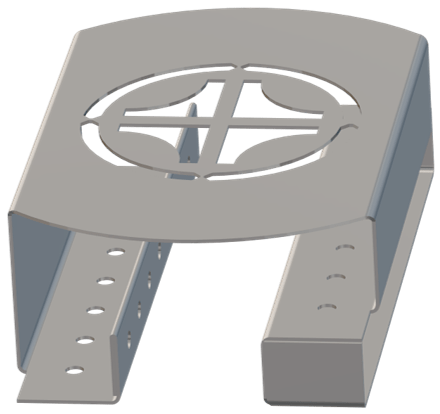

JFY BEND 支持 20 多种不同样式的冲头、模具、冲模和模架以及适配器,使其成为压力机制动器编程和工具优化方面最通用的解决方案之一。软件预装了工具目录,其中包括各种常用工具。

通过将全面的模具库与先进的编程功能相结合,JFY BEND 使制造商能够缩短设置时间、提高零件质量,并最大限度地利用其压力折弯机。

除折弯解决方案外,JFY BEND 还支持人体工程学优化,以提高操作员的安全性和效率。工件定位重量分配、旋转引导和翻转优化等功能有助于减轻身体负担,改善操作,并确保在压力机折弯机上进行更安全、更舒适的操作。JFY BEND 将工具智能化与以操作员为中心的考虑因素相结合,为生产效率和工作场所人体工程学提供了完整的解决方案,最终有助于提高零件质量,使制造工作流程更加顺畅。

JFY BEND 采用先进的几何适应策略,解决了零件设计和制造中的常见难题。无论是平面图案还是三维模型,它都能调整零件的几何形状,确保在整个制造过程中精确地生产每个零件。

有了 JFY BEND,工程师和操作员可以放心地从设计转向生产,因为他们知道软件提供的可操作指导、自动修正和可生产性检查可以节省时间、降低成本并提高整体零件质量。

将离线折弯与压力折弯机人机界面连接起来,可直接在机器上传输和执行程序,从而减少设置时间并消除手动错误。操作员可以加载作业、查看序列并进行实时调整,同时仍然遵循优化的离线程序。这种集成可确保精确、一致的弯曲,最大限度地减少材料浪费,提高生产率,从而节省时间和金钱。

JFY BEND 与 TJS-90 控制源相同,可确保同步兼容性。

All our JFY laser machines are delivered standard with JFY CUT, our powerful offline laser programming and machine control software. This ensures every machine is production-ready within seconds — no complex setup or extra installation required. Linking offline programming with the laser’s HMI allows complete cutting jobs to be transferred and executed directly on the machine, eliminating manual input and reducing operator-dependent errors. Operators can load nests, review cut paths, and monitor production while still following the optimised offline program.

This integration guarantees accurate geometry, consistent cut quality, improved material utilisation, and reduced rework — delivering real, measurable savings on material and machine hours. JFY CUT shares the same software foundation as the Tetris CNC control, ensuring full compatibility and perfectly synchronised performance across your entire laser cutting workflow.

体验直观的界面、强大的模拟功能以及与我们的压力机制动器的无缝集成。.

JFY Plus 是用于激光切割和折弯的革命性一体化离线编程解决方案,可将您的折弯软件提升到新的水平。得益于其逆向工作流程,编程只需几秒钟,而不是几分钟--简单、精确、直观,任何人都能做到。.

会员资格

到期