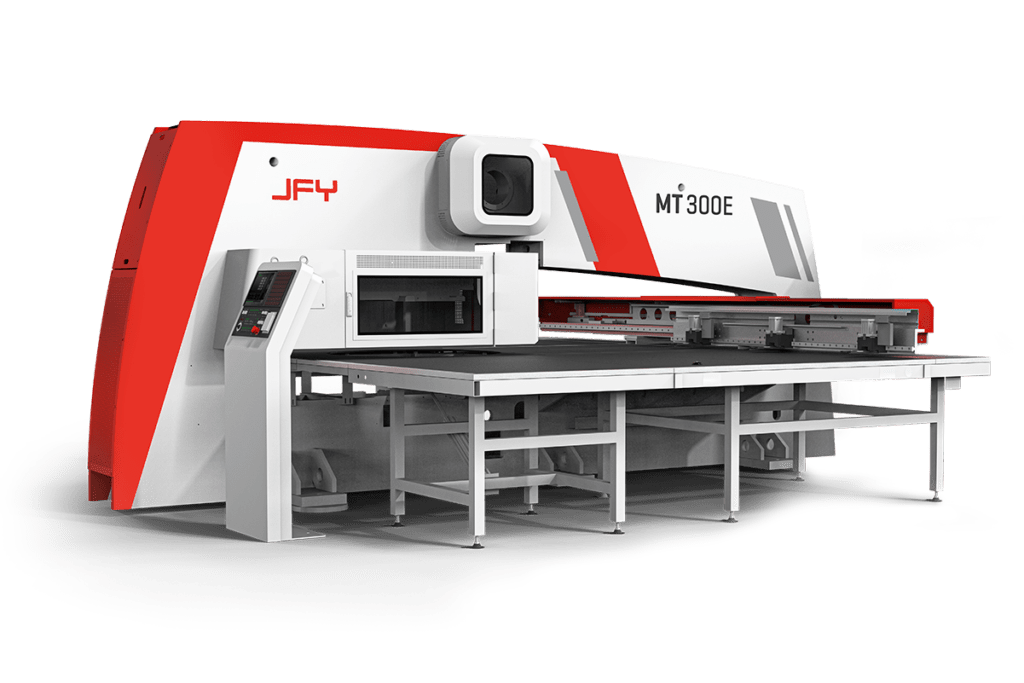

MT SERIES

The MT Series offers maximum performance at low investment costs. With over 20% market share in China, the MT300E is the leader in its class. Flexible for different formats, efficient thanks to customised automation solutions, and user-friendly thanks to the stable FANUC CNC system – for reliable and versatile production.

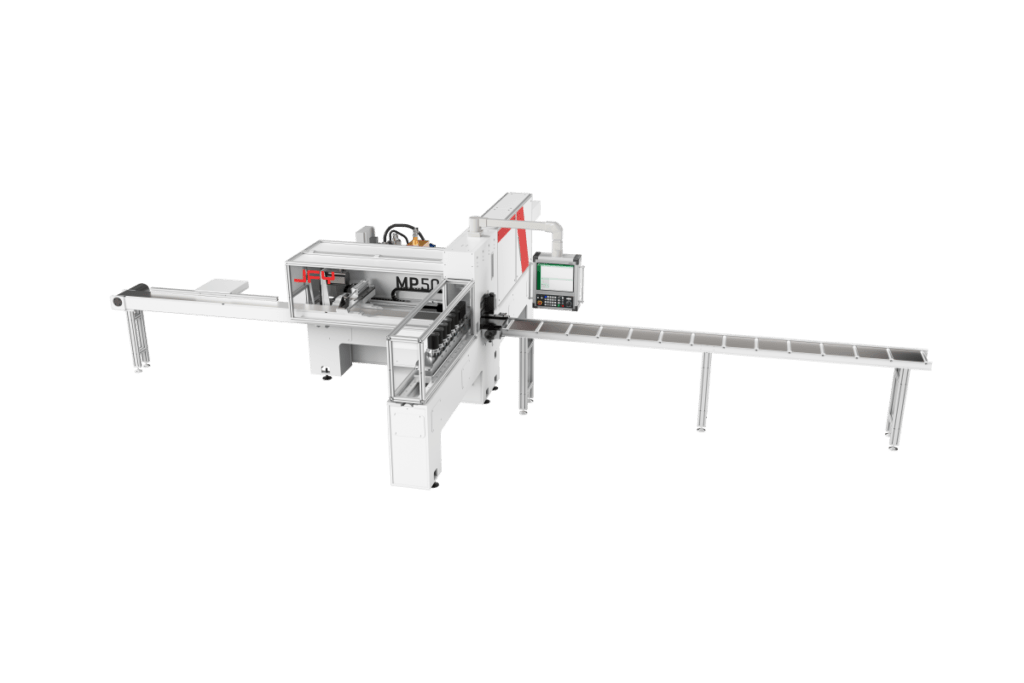

MP50 SERIES

The MP50 Series is used for the professional processing of busbars with functions such as punching, cutting and embossing. The innovative T-shaped design combines compact aesthetics with high stability. With 7+1+1 and 8+1 tool stations, it offers maximum flexibility and efficiency. The hydraulic drive ensures quiet, stable operation and continuous production.

MB40 SERIES

The MB40 Bending Machine is suitable for versatile bending processes for maximum precision.

With its ability to perform flat, vertical, twist and U-bends, it masters every task. Thanks to its servo motor and electronic angle system, it guarantees precise results. Simple operation thanks to comprehensive software for customised programming and automatic nesting.

VR SERIES

The VR6 stands out with its high-precision engineering and user-friendly design, making it ideal for various industrial applications. Its robust construction ensures stable operation, while advanced automation features streamline the shearing process. With a range of configurations and optional enhancements, the VR6 adapts to diverse processing needs, ensuring efficient and reliable performance. Safety is paramount, with integrated systems that meet stringent standards.

TPE 8 SERIES

Efficient bending, environmentally friendly and low-maintenance – with the direct-drive servo motor, the TPE8 series increases processing efficiency by more than 1.5 times, reduces energy costs by over 70% and delivers precise bending results at the same time. Compact in design, flexible in installation and easy to maintain – for maximum productivity and sustainability.

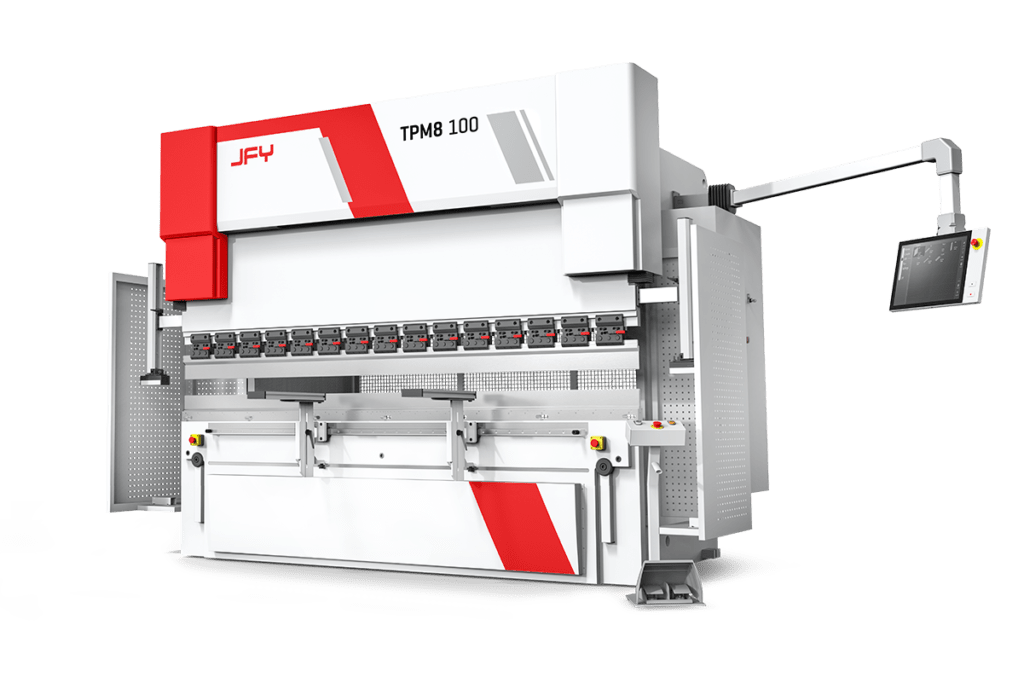

TPM 8 SERIES

Maximum productivity, simple operation and maximum safety – the TPM offers the best price-performance ratio. Thanks to its robust frame, automatic compensation and user-friendly controls, it delivers precise results in record time. With a dense service network and customised starter kits, it ensures a fast production start and maximum efficiency.

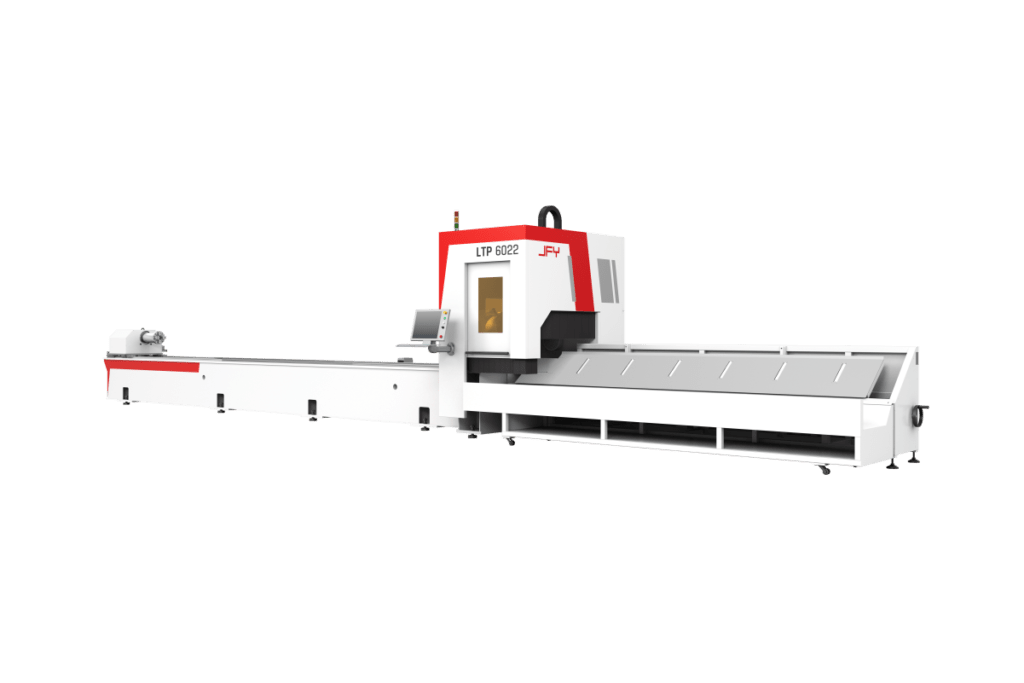

LTP SERIES

The LTP series delivers high-precision tube processing with superior productivity and ease of use. It features built-in protective glasses for enhanced cutting head durability and precision, dual cooling circuits for stability, and auto-focus for efficient cutting. The FSCUT5000 with EtherCAT BUS system offers flexible, real-time control, while JFY’s advanced fiber laser technology ensures stable, high-frequency cutting with excellent seam quality and low maintenance.

BFC SERIES

A high-performance laser machine which opens a broad spectrum of cutting applications for various industries.

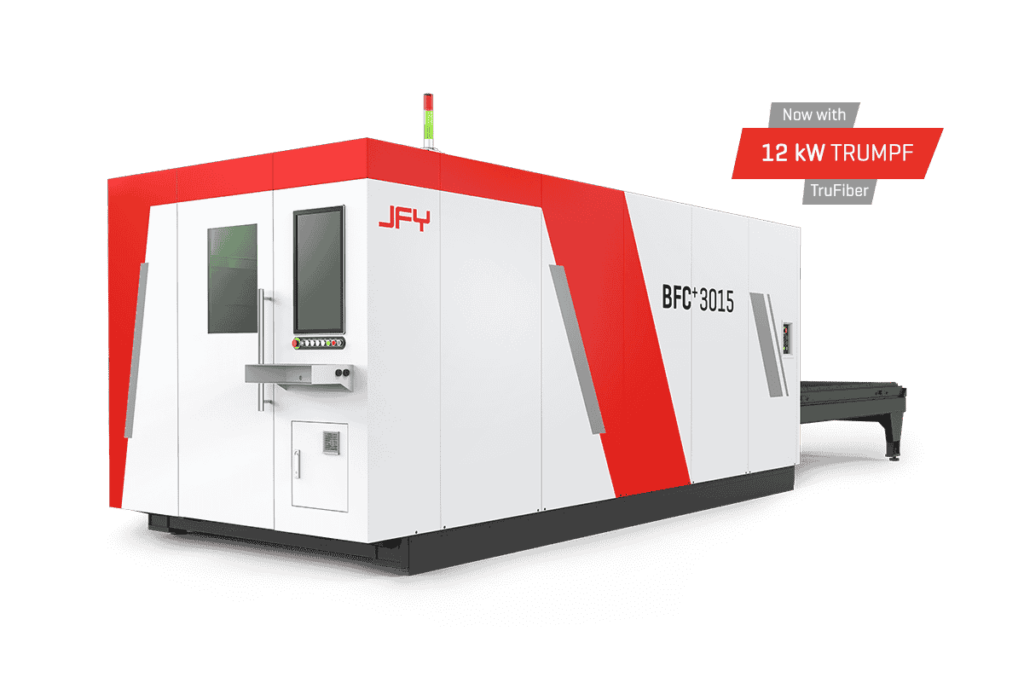

BFC PLUS SERIES

The BFC+ sets a new standard in productivity and cost-effectiveness with its TRUMPF TruFiber Laser, offering exceptional flexibility and reliability. It features an upgraded control system with a large screen for online programming, high safety standards with a fully enclosed machine, and proven optics for superior cutting quality. The Precitec cutting unit ensures high-speed, stable processing of thick materials, and easy maintenance.