Improved Efficiency – Programs can be prepared in advance without tying up the press brake, reducing machine idle time.

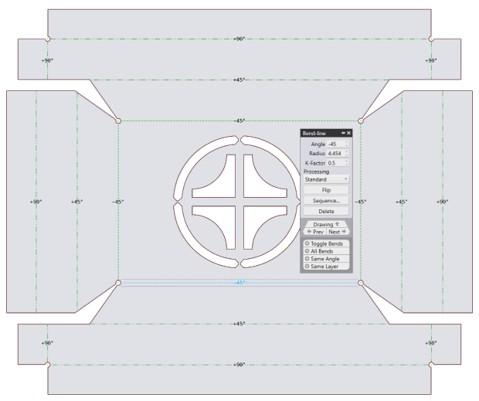

Offline programming allows simulation of bend sequences and collision detection, minimizing operator mistakes.

Facilitates programming for multi-bend or intricate geometries that would be difficult to calculate manually

Reduces trial-and-error on the machine; tooling and sequences can be optimized virtually first.

Less scrap, lower machine downtime, and faster throughput reduce overall production costs.

Less scrap, lower machine downtime, and faster throughput reduce overall production costs.

JFY BEND supports a wide range of import formats, including DXF, DWG, ACIS, Inventor, CATIA, I-Deas, IGES, MetaCAM, SolidEdge, Pro-E, and SolidWorks, making it highly compatible with many CAD formats without the need for time-consuming file conversions, maintaining the integrity and accuracy of the original part geometry.

In addition, JFY BEND features a powerful and user-friendly editor that allows you to convert 2D designs into fully realized 3D models. This capability enables quick validation, modification, and preparation of parts for bending processes, reducing design errors and streamlining production.

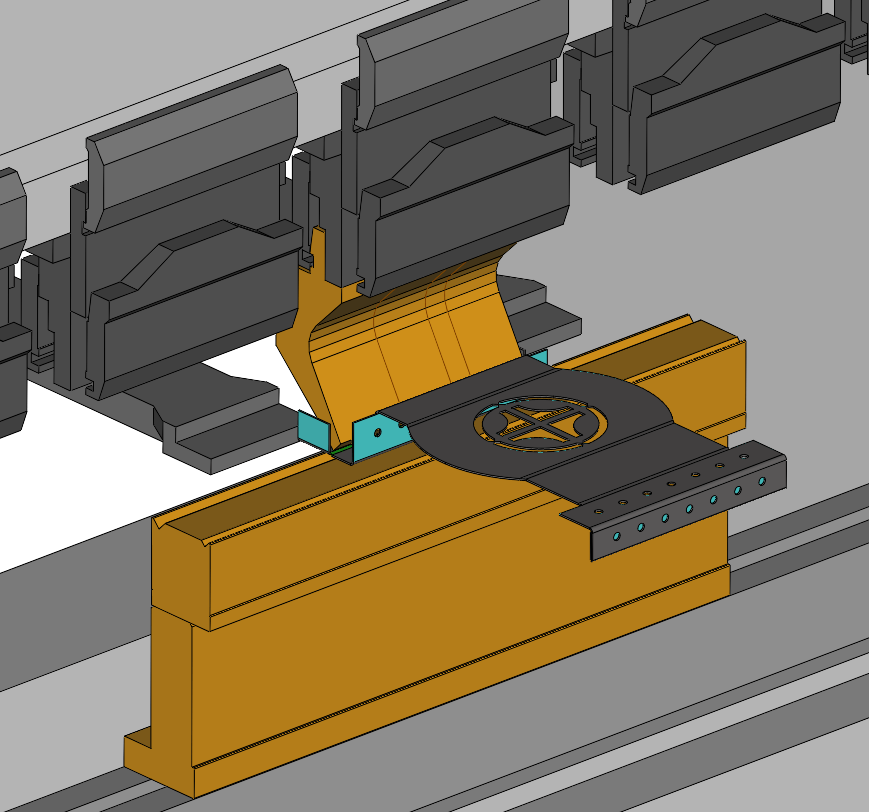

JFY BEND features smart bending solutions designed to optimize tooling selection, part placement, and multistage setups, helping manufacturers achieve faster, more accurate, and more efficient production. By analyzing the bending process, the software can recommend the best tools and sequences, reduce unnecessary tool changes, and ensure that parts are processed in the most effective order, saving time and minimizing errors.

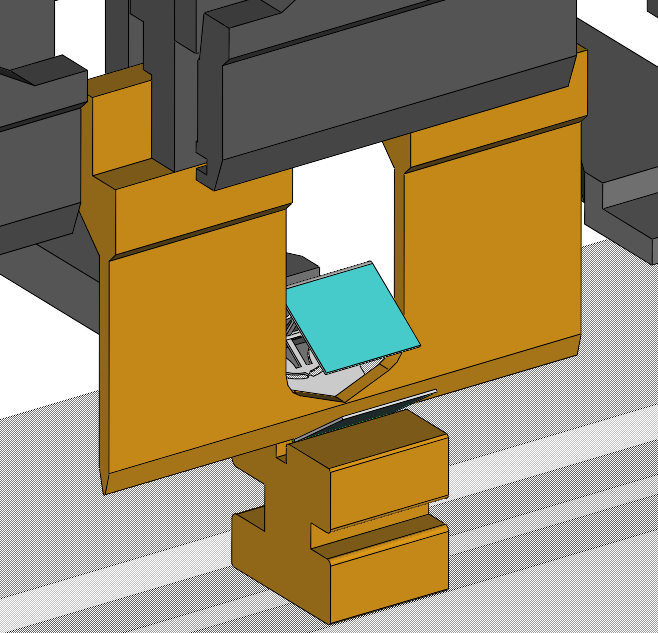

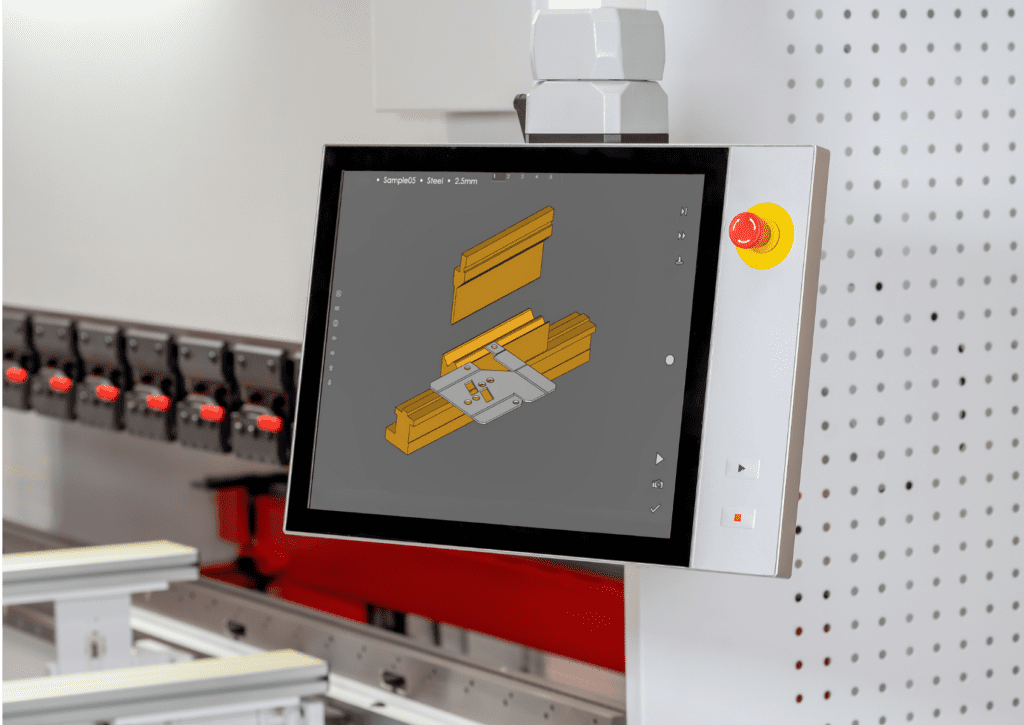

JFY BEND also features a fully immersive editor where you can fully interact with the items you see on the screen like gauges, tooling, part and tool holders.

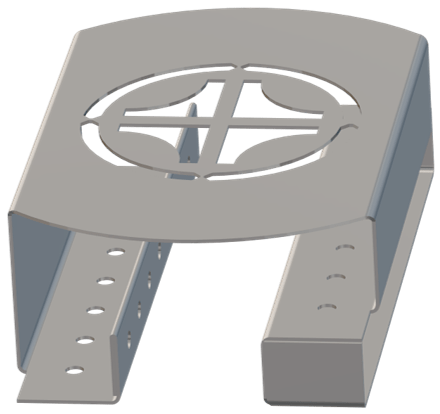

JFY BEND supports over 20 different styles of punches, dies, punch and die holders, and adapters, making it one of the most versatile solutions for press brake programming and tooling optimization. The software comes with preloaded tool catalogs that include a wide variety of commonly used tools.

By combining a comprehensive tooling library with advanced programming capabilities, JFY BEND empowers manufacturers to reduce setup times, improve part quality, and get the most out of their press brake machines.

In addition to bending solutions, JFY BEND supports ergonomic optimization to improve operator safety and efficiency. Features such as part positioning for weight distribution, rotation guidance, and flip optimization help reduce physical strain, improve handling, and ensure safer, more comfortable operation at the press brake. By combining tooling intelligence with operator-focused considerations, JFY BEND provides a complete solution for both production efficiency and workplace ergonomics, ultimately contributing to higher-quality parts and a smoother manufacturing workflow.

JFY BEND tackles common challenges in both part design and manufacturing by using advanced geometry adaptation strategies. Whether working with flat patterns or 3D models, it can adjust part geometries to ensure that every component can be produced accurately throughout the entire manufacturing process.

With JFY BEND, engineers and operators can confidently move from design to production, knowing that the software provides actionable guidance, automatic corrections, and producibility checks that save time, reduce costs, and improve overall part quality.

Our average automated solution is available in 1 – 2 seconds!

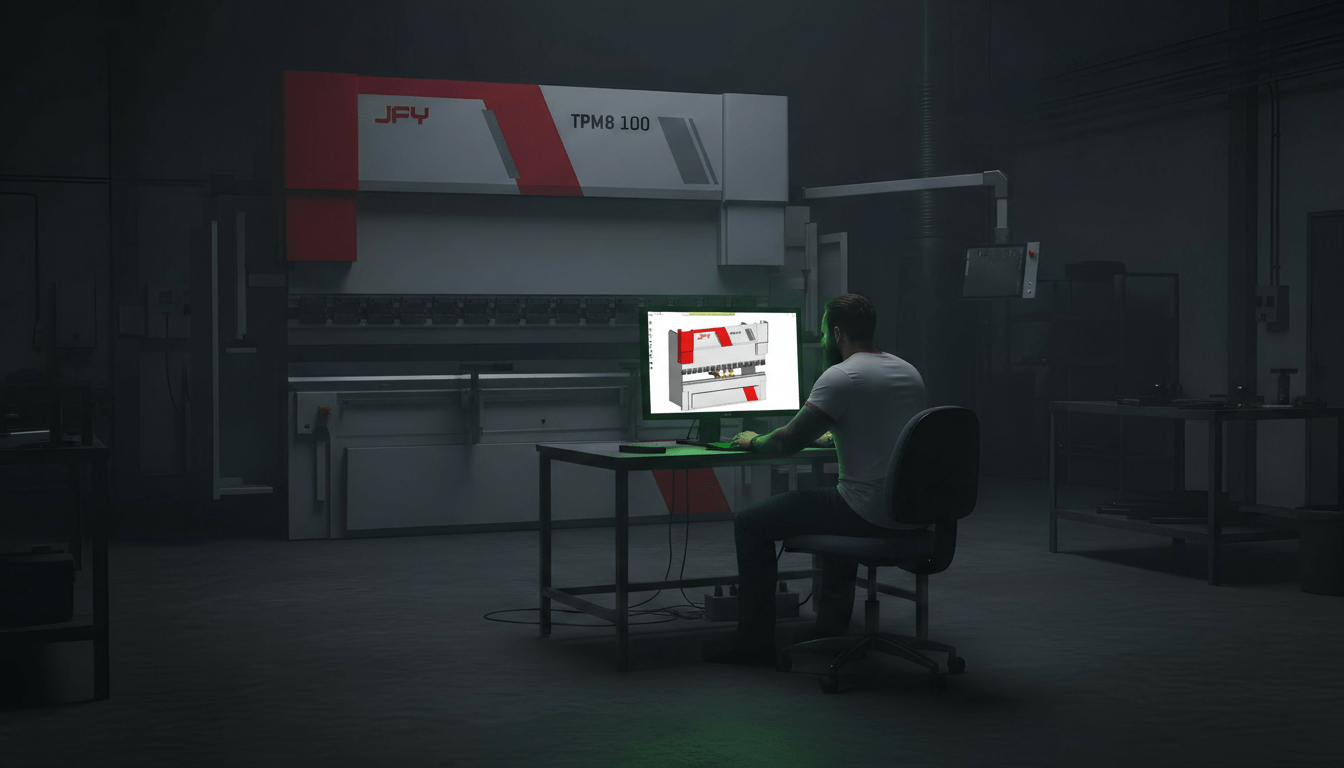

Linking offline bending with the press brake HMI allows programs to be transferred and executed directly on the machine, reducing setup time and eliminating manual errors. Operators can load jobs, review sequences, and make real-time adjustments while still following the optimized offline program. This integration ensures precise, consistent bends, minimizes material waste, and boosts productivity — saving both time and money.

JFY BEND is the same source as TJS-90 control, ensuring that compatibility is syncronised.

All our JFY press brakes are delivered standard with JFY BEND, our powerful offline bending and control software. This ensures every machine is ready for production within seconds — no complex setup or additional installation required. Linking offline bending with the press brake HMI allows programs to be transferred and executed directly on the machine, reducing setup time and eliminating manual errors. Operators can load jobs, review bend sequences, and make real-time adjustments while still following the optimized offline program.This integration guarantees precise and consistent bending results, minimizes material waste, and boosts productivity — saving both time and money. JFY BEND shares the same software foundation as the TJS-90 control, ensuring full compatibility and synchronized performance across your production line.

Experience the intuitive interface, powerful simulation, and seamless integration with our press brakes.

Take your bending software to the next level — with JFY Plus, the revolutionary all-in-one offline programming solution for laser cutting and bending. Thanks to its reversed workflow, programming happens in seconds instead of minutes — simple, precise, and so intuitive that anyone can do it.

Associação

Expirações