Los programas pueden prepararse con antelación sin necesidad de inmovilizar la plegadora, lo que reduce el tiempo de inactividad de la máquina.

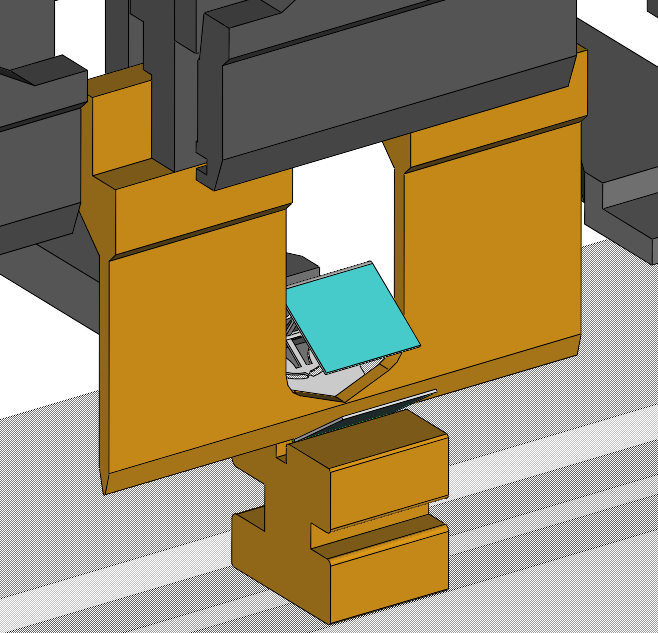

La simulación completa de secuencias de curvas, la detección de colisiones y las alertas de diseño ayudan a reducir los posibles errores.

Soluciones multidoblado o multiconfiguración calculadas sin esfuerzo en función de las herramientas disponibles y los parámetros de la máquina.

Reduzca el ensayo y error en su máquina, las herramientas y las secuencias pueden optimizarse fuera de línea.

Menos piezas desechadas, menos tiempo de inactividad de la máquina y un rendimiento más rápido reducen los costes generales de producción.

Totalmente integrado con el controlador HMI JFY TJS-90.

JFY BEND admite una amplia gama de formatos de importación, incluidos DXF, DWG, ACIS, Inventor, CATIA, I-Deas, IGES, MetaCAM, SolidEdge, Pro-E y SolidWorks, lo que lo hace altamente compatible con muchos formatos CAD sin necesidad de realizar conversiones de archivos que requieren mucho tiempo, manteniendo la integridad y precisión de la geometría original de la pieza.

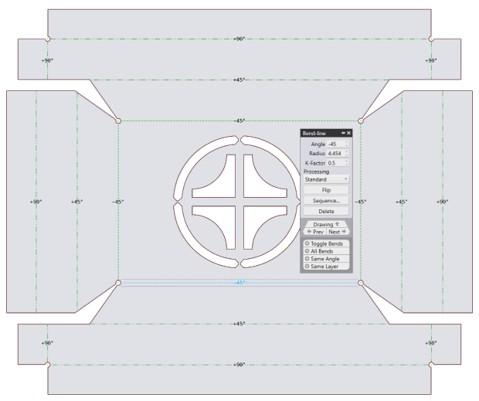

Además, JFY BEND cuenta con un editor potente y fácil de usar que permite convertir diseños 2D en modelos 3D totalmente realizados. Esta capacidad permite validar, modificar y preparar rápidamente las piezas para los procesos de plegado, reduciendo los errores de diseño y agilizando la producción.

JFY BEND ofrece soluciones de plegado inteligentes diseñadas para optimizar la selección de herramientas, la colocación de piezas y las configuraciones multietapa, ayudando a los fabricantes a conseguir una producción más rápida, precisa y eficaz. Al analizar el proceso de plegado, el software puede recomendar las mejores herramientas y secuencias, reducir los cambios innecesarios de herramientas y garantizar que las piezas se procesen en el orden más eficaz, ahorrando tiempo y minimizando los errores.

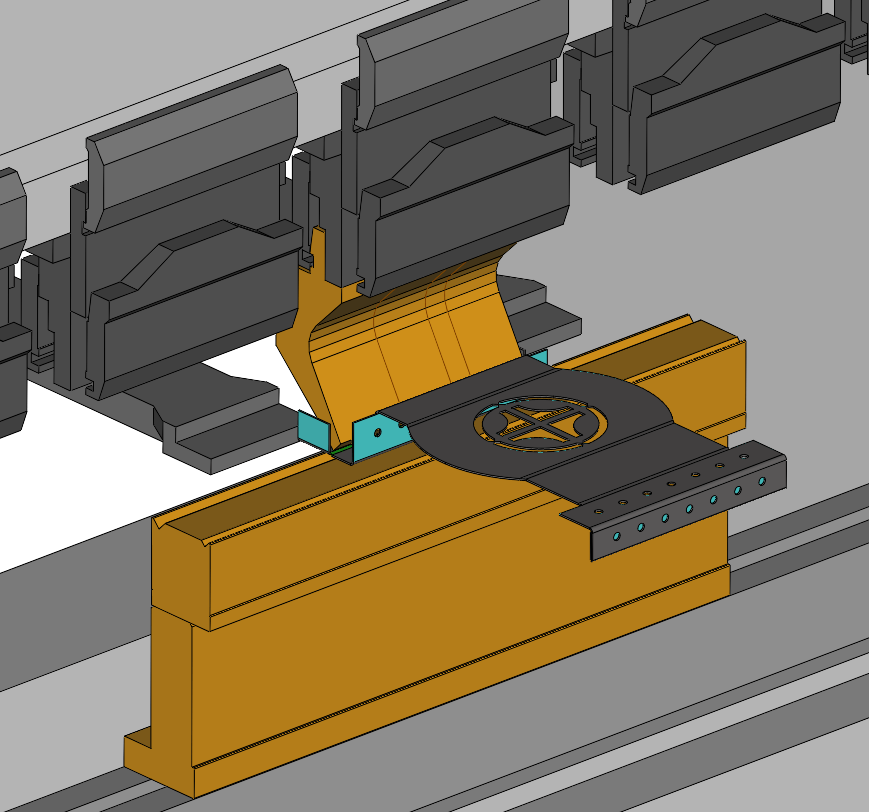

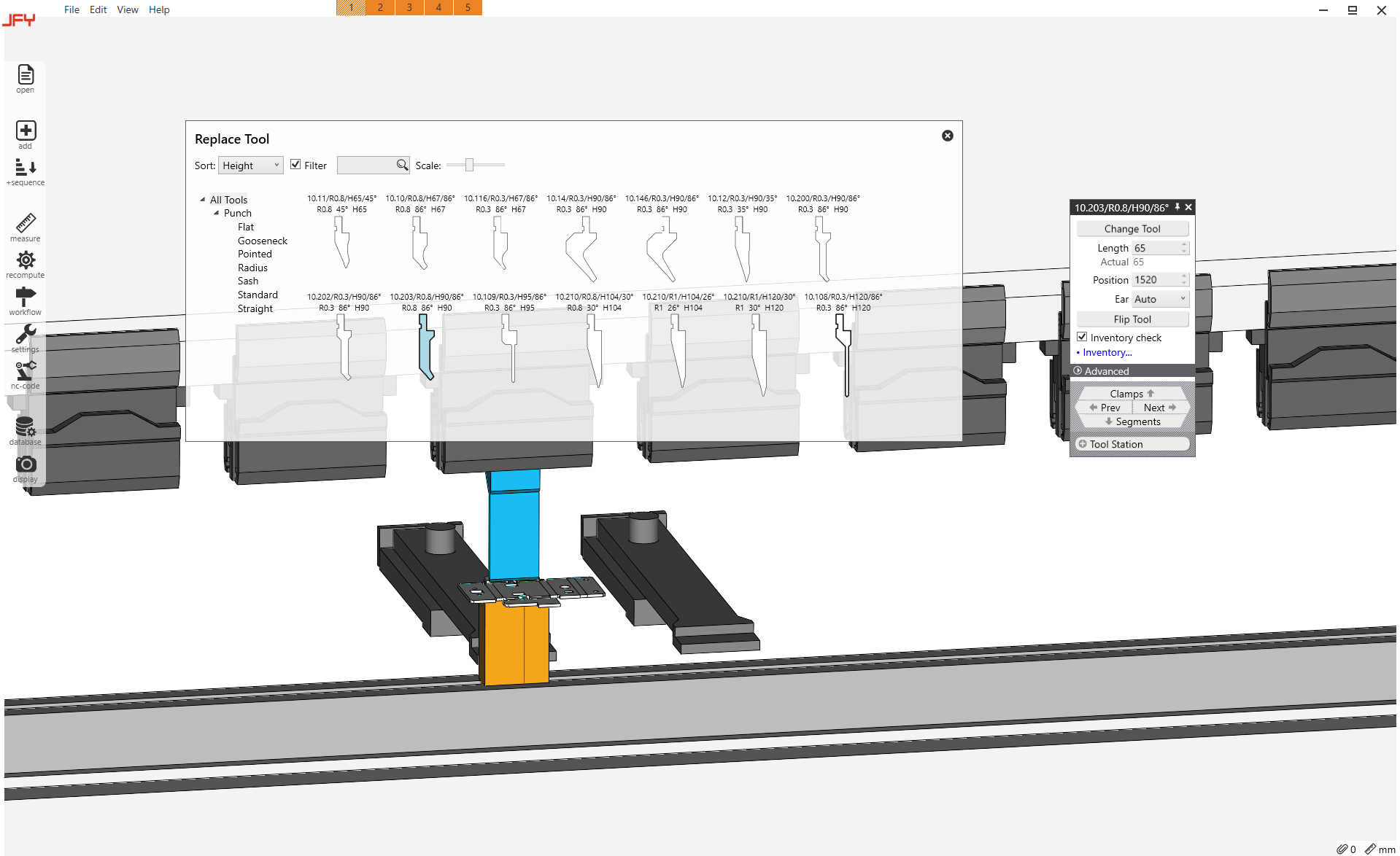

JFY BEND también cuenta con un editor totalmente inmersivo en el que se puede interactuar plenamente con los elementos que se ven en la pantalla, como calibres, herramientas, piezas y portaherramientas.

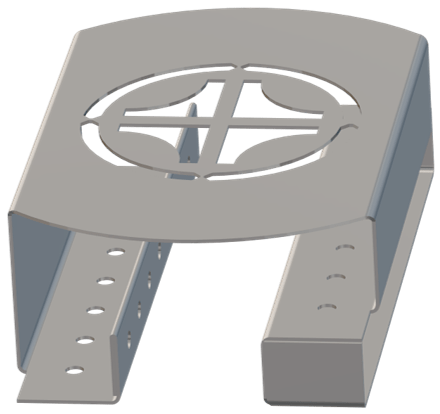

JFY BEND admite más de 20 estilos diferentes de punzones, matrices, soportes para punzones y matrices y adaptadores, lo que lo convierte en una de las soluciones más versátiles para la programación de prensas plegadoras y la optimización de herramientas. El software viene con catálogos de herramientas precargados que incluyen una amplia variedad de herramientas de uso común.

Al combinar una completa biblioteca de herramientas con funciones de programación avanzadas, JFY BEND permite a los fabricantes reducir los tiempos de preparación, mejorar la calidad de las piezas y sacar el máximo partido de sus prensas plegadoras.

Además de las soluciones de plegado, JFY BEND soporta la optimización ergonómica para mejorar la seguridad y eficiencia del operario. Funciones como el posicionamiento de piezas para la distribución del peso, la guía de rotación y la optimización del volteo ayudan a reducir el esfuerzo físico, mejoran la manipulación y garantizan un funcionamiento más seguro y cómodo en la plegadora. Al combinar la inteligencia de las herramientas con consideraciones centradas en el operario, JFY BEND proporciona una solución completa tanto para la eficiencia de la producción como para la ergonomía del lugar de trabajo, contribuyendo en última instancia a piezas de mayor calidad y a un flujo de trabajo de fabricación más fluido.

JFY BEND aborda los retos habituales tanto en el diseño como en la fabricación de piezas mediante estrategias avanzadas de adaptación de la geometría. Tanto si trabaja con patrones planos como con modelos 3D, puede ajustar las geometrías de las piezas para garantizar que cada componente pueda producirse con precisión a lo largo de todo el proceso de fabricación.

Con JFY BEND, los ingenieros y operarios pueden pasar con confianza del diseño a la producción, sabiendo que el software proporciona orientación práctica, correcciones automáticas y comprobaciones de producibilidad que ahorran tiempo, reducen costes y mejoran la calidad general de las piezas.

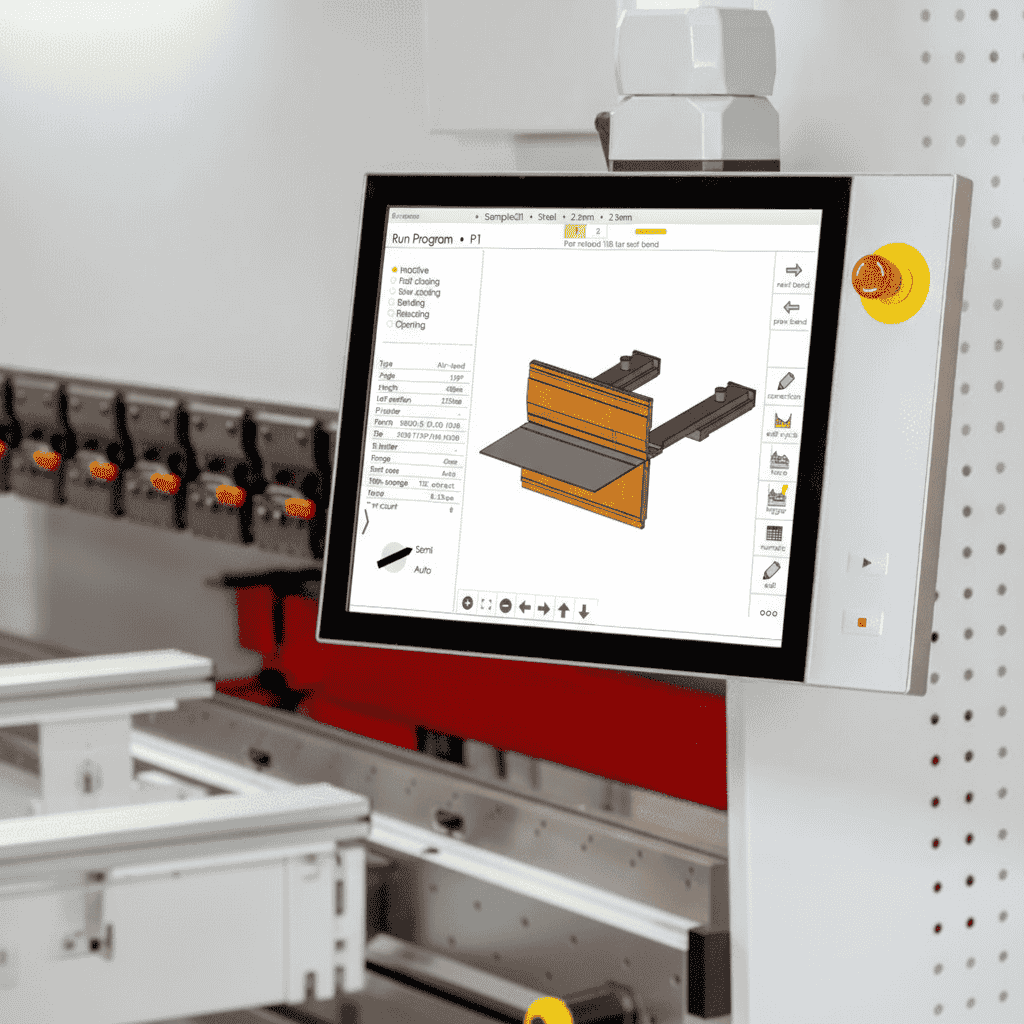

La vinculación del plegado fuera de línea con la HMI de la plegadora permite transferir los programas y ejecutarlos directamente en la máquina, lo que reduce el tiempo de configuración y elimina los errores manuales. Los operarios pueden cargar trabajos, revisar secuencias y realizar ajustes en tiempo real mientras siguen el programa offline optimizado. Esta integración garantiza plegados precisos y uniformes, minimiza el desperdicio de material y aumenta la productividad, ahorrando tiempo y dinero.

JFY BEND es la misma fuente que el control TJS-90, lo que garantiza la sincronización de la compatibilidad.

Nuestra solución automatizada media está disponible en 1 ó 2 segundos.

Todas nuestras plegadoras JFY se entregan de serie con JFY BEND, nuestro potente software de plegado y control offline. Esto garantiza que todas las máquinas estén listas para la producción en cuestión de segundos, sin necesidad de configuraciones complejas ni instalaciones adicionales. La vinculación del plegado offline con la HMI de la plegadora permite transferir y ejecutar los programas directamente en la máquina, lo que reduce el tiempo de configuración y elimina los errores manuales. Los operarios pueden cargar trabajos, revisar secuencias de plegado y realizar ajustes en tiempo real mientras siguen el programa offline optimizado. Esta integración garantiza resultados de plegado precisos y consistentes, minimiza el desperdicio de material y aumenta la productividad, ahorrando tiempo y dinero. JFY BEND comparte la misma base de software que el control TJS-90, lo que garantiza una compatibilidad total y un rendimiento sincronizado en toda la línea de producción.

Experimente la interfaz intuitiva, la potente simulación y la perfecta integración con nuestras plegadoras.

Lleve su software de plegado al siguiente nivel con JFY Plus, la revolucionaria solución de programación offline todo en uno para corte y plegado por láser. Gracias a su flujo de trabajo invertido, la programación se realiza en segundos en lugar de minutos: sencilla, precisa y tan intuitiva que cualquiera puede hacerlo.

Afiliación

Expira en